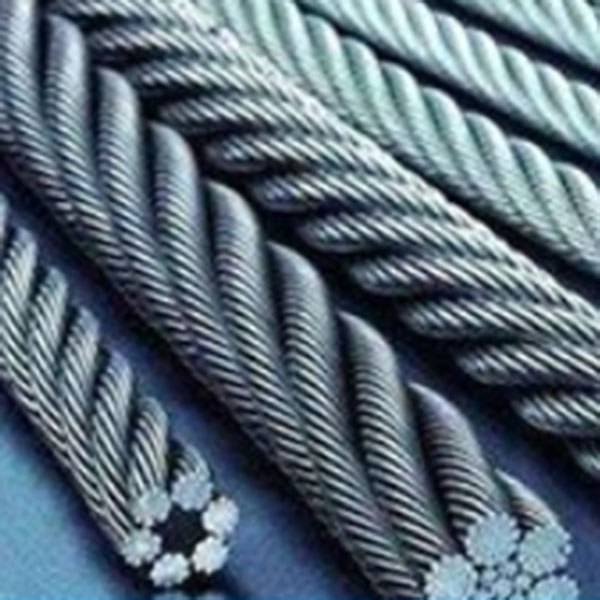

Cabluri de sârmă de oțel de înaltă calitate pentru lift

1. Această specificație este potrivită pentru cabluri de sârmă cu limitator de viteză, lifturi cu viteză redusă și sarcină redusă

2. De asemenea, putem personaliza în funcție de cerințele dumneavoastră.

| Diametrul nominal al cablului | 6*19S+PP | Sarcină minimă de rupere | |||

| Greutate aproximativă | Tracțiune dublă, Mpa | Tracțiune unică, Mpa | |||

| 1370/1770 | 1570/1770 | 1570 | 1770 | ||

| mm | kg/100 m | kN | kN | kN | kN |

| 6 | 12.9 | 17,8 | 19,5 | 18,7 | 21 |

| 8 | 23 | 31,7 | 34,6 | 33.2 | 37,4 |

1. Miez din fibră naturală (NFC): Potrivit pentru cablul de oțel al mașinii de tracțiune cu o viteză nominală ≤ 2,0 m/s

2. Înălțimea clădirii ≤80M

| Diametrul nominal al cablului | 8*19S+NFC | Sarcină minimă de rupere | |||

| Greutate aproximativă | Tracțiune dublă, Mpa | Tracțiune unică, Mpa | |||

| 1370/1770 | 1570/1770 | 1570 | 1770 | ||

| mm | kg/100 m | kN | kN | kN | kN |

| 8 | 21,8 | 28.1 | 30,8 | 29,4 | 33.2 |

| 9 | 27,5 | 35,6 | 38,9 | 37,3 | 42 |

| 10 | 34 | 44 | 48.1 | 46 | 51,9 |

| 11 | 41.1 | 53.2 | 58.1 | 55,7 | 62,8 |

| 12 | 49 | 63,3 | 69,2 | 66,2 | 74,7 |

| 13 | 57,5 | 74,3 | 81,2 | 77,7 | 87,6 |

| 14 | 66,6 | 86,1 | 94,2 | 90,2 | 102 |

| 15 | 76,5 | 98,9 | 108 | 104 | 117 |

| 16 | 87 | 113 | 123 | 118 | 133 |

| 18 | 110 | 142 | 156 | 149 | 168 |

| 19 | 123 | 159 | 173 | 166 | 187 |

| 20 | 136 | 176 | 192 | 184 | 207 |

| 22 | 165 | 213 | 233 | 223 | 251 |

1. Pentru IWRC, viteză > 4,0 m/s, înălțimea clădirii > 100 m

2. Pentru IWRF, 2.0< viteză ≤4.0m/s, Înălțimea clădirii ≤100m

| Diametrul nominal al cablului | 8*19S | Sarcină minimă de rupere | |||||||

| Greutate aproximativă | Tracțiune unică, Mpa | ||||||||

| 1570 | 1620 | 1770 | |||||||

| IWRC | IWRF | IWRC | IWRF | IWRC | IWRF | IWRC | IWRF | ||

| mm | kg/100 m | kN | kN | / | kN | ||||

| 8 | 26 | 25,9 | 35,8 | 35.2 | 36,9 | 35.2 | 40,3 | 39,6 | |

| 9 | 33 | 32,8 | 45,3 | 44,5 | 46,7 | 45,9 | 51 | 50,2 | |

| 10 | 40,7 | 40,5 | 55,9 | 55 | 57,7 | 56,7 | 63 | 62 | |

| 11 | 49.2 | 49 | 67,6 | 66,5 | 69,8 | 68,6 | 76,2 | 75 | |

| 12 | 58,6 | 58,3 | 80,5 | 79,1 | 83 | 81,6 | 90,7 | 89,2 | |

| 13 | 68,8 | 68,4 | 94,5 | 92,9 | 97,5 | 98,5 | 106 | 105 | |

| 14 | 79,8 | 79,4 | 110 | 108 | 113 | 111 | 124 | 121 | |

| 15 | 91,6 | 91.1 | 126 | 124 | 130 | 128 | 142 | 139 | |

| 16 | 104 | 104 | 143 | 141 | 148 | 145 | 161 | 159 | |

| 18 | 132 | 131 | 181 | 178 | 187 | 184 | 204 | 201 | |

| 19 | 147 | 146 | 202 | 198 | 208 | 205 | 227 | 224 | |

| 20 | 163 | 162 | 224 | 220 | 231 | 227 | 252 | 248 | |

| 22 | 197 | 196 | 271 | 266 | 279 | 274 | 305 | 300 | |

Cele mai mici ascensoare pentru pasageri sunt utilizate pentru cabluri de sârmă pentru ascensoare. În zonele rezidențiale comerciale, specificațiile cablurilor de sârmă pentru ascensoare sunt în general 8*19S+FC-8mm, 8*19S+FC-10mm. Centrele comerciale utilizează specificații pentru cabluri de ascensoare puțin mai mari, de 12mm, 13mm, și specificații pentru cabluri de oțel pentru ascensoare de sarcină, de 12mm, 13mm și 16mm în diametru.

La comandarea cablului de oțel, vi se solicită să ne furnizați informațiile complete, așa cum sunt specificate mai jos:

1. Scop: Pentru ce frânghie va fi utilizată;

2. Dimensiune: Diametrul frânghiei în milimetri sau inci;

3. Construcție: Numărul de fire, numărul de fire per fir și tipul de construcție a suportului;

4. Tipul miezului: miez din fibră (FC), miez independent din cablu metalic (IWRC) sau miez independent din fir metalic (IWSC);

5. Așezare: Așezare regulată dreapta, așezare regulată stânga, așezare lungă dreapta, așezare lungă stânga,

6. Material: Oțel strălucitor (negalvanizat), galvanizat sau inoxidabil;

7. Calitatea sârmei: Rezistența la tracțiune a firelor;

8. Lubrifiere: Dacă este dorită sau nu lubrifierea și lubrifiantul necesar;

9. Lungime: lungimea cablului metalic;

10. Ambalare: În bobine învelite cu hârtie uleiată și pânză de iepure sau pe role de lemn;

11. Cantitate: După numărul de bobine sau role, după lungime sau greutate;

12. Observații: Mărci de expediere și orice alte cerințe speciale.

În timpul funcționării pe termen lung, uleiul de ungere de pe cablul metalic va scădea treptat. Prin urmare, este necesar ca acesta să fie lubrifiat în mod regulat, ceea ce poate prelungi durata de viață a cablului metalic, reduce uzura și previne rugina prin relubrifiere. Comparativ cu un cablu metalic complet lubrifiat, durata de viață a unui cablu metalic uscat poate fi redusă cu până la 80%! Relubrifierea cablului metalic joacă un rol foarte important. De obicei, alegem uleiul de ungere T86, care este un lichid foarte subțire care poate pătrunde ușor în interiorul cablului metalic. Este nevoie doar de o pensulă sau de un butoi portabil de 1 litru pentru a-l pulveriza. Locul de utilizare ar trebui să fie acolo unde cablul metalic atinge scripetele de tracțiune sau roata de ghidare, astfel încât lubrifiantul cablului metalic să poată curge mai ușor în cablu.